In the fast-evolving landscape of manufacturing, the importance of efficiency and performance in production processes is paramount. As industries strive to meet growing consumer demands, the role of advanced filling machines becomes increasingly crucial. According to a recent report by Market Research Future, the global filling machine market is expected to reach $5 billion by 2025, growing at a CAGR of 4.5%. This growth is driven by technological advancements and the integration of automation, making it essential for businesses to invest in the right filling machines to optimize their production lines.

Industry expert Dr. John Smith, a prominent figure in filling machine technology, emphasizes the significance of choosing the right machines: “The efficiency of filling machines directly impacts production speed and product quality. Investing in high-performance machines can lead to substantial cost savings and improved market competitiveness.” As manufacturers prepare for the future, the 2025 Top 10 Filling Machines will serve as a guide to help companies identify the most effective solutions for enhancing their operational capabilities. In this article, we will explore these top filling machines that promise to deliver maximum performance and address the critical needs of various sectors.

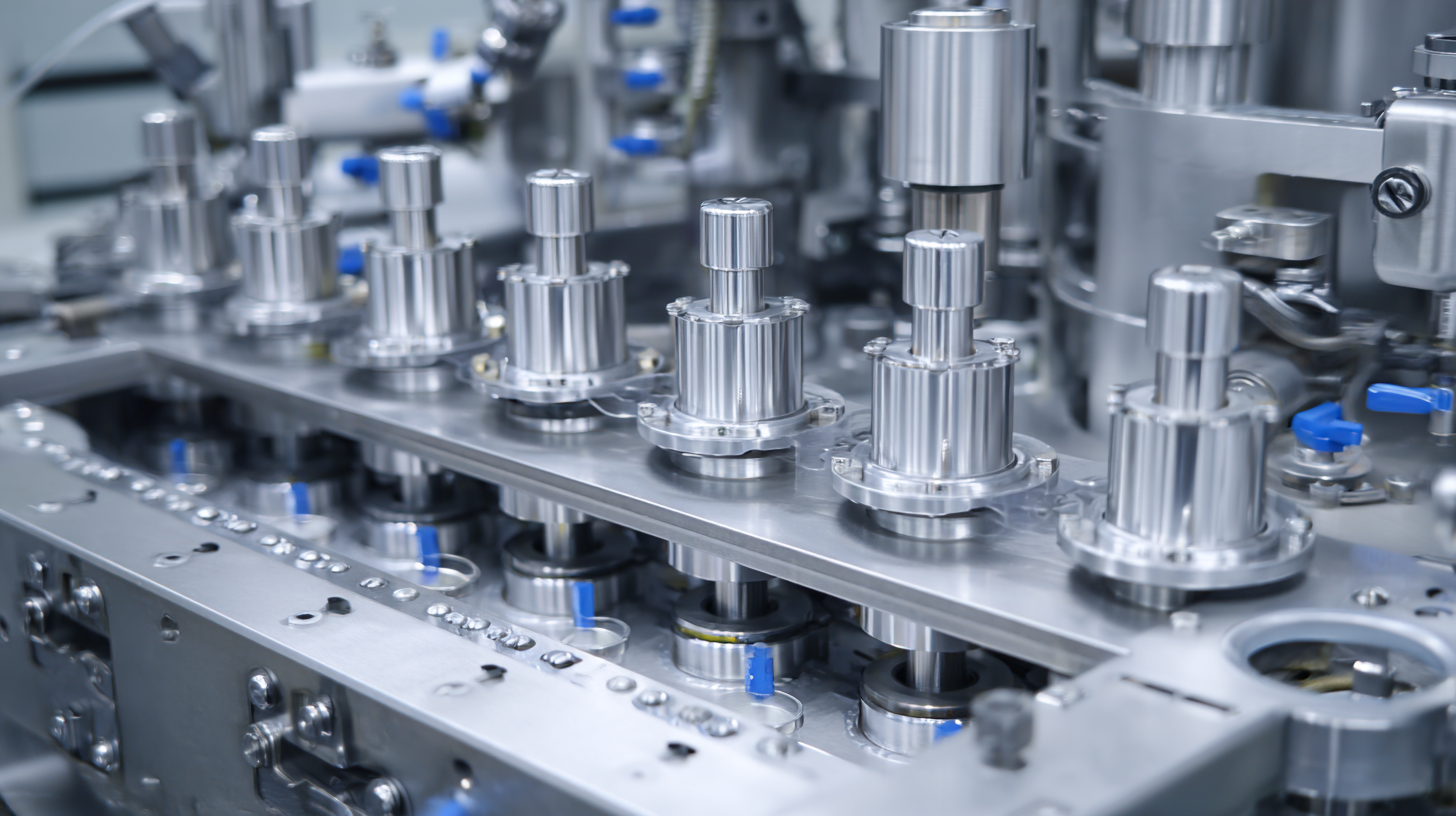

The landscape of filling machines is set to transform dramatically in 2025, thanks to groundbreaking technologies that enhance both efficiency and performance. As industries strive for greater output and precision, innovations such as Artificial Intelligence (AI) and the Internet of Things (IoT) are becoming integral to modern filling operations. AI-driven algorithms can analyze real-time data to optimize filling speeds and accuracy, minimizing waste and maximizing productivity. This intelligent automation not only streamlines production processes but also reduces labor costs, making it an appealing solution for manufacturers looking to stay competitive.

Additionally, advancements in sensor technology are playing a crucial role in the evolution of filling machines. High-precision sensors can detect discrepancies in fill levels and container integrity, ensuring that each product meets quality standards before it leaves the production line. Coupled with enhanced software platforms that provide comprehensive analytics, these machines allow for predictive maintenance and advanced scheduling. As a result, manufacturers can avoid costly downtime and allocate resources more effectively. These innovations are set to redefine efficiency in the filling industry, paving the way for smarter, faster, and more reliable production systems in the coming years.

| Machine Model | Type | Filling Speed (BPM) | Accuracy (%) | Power Consumption (kW) | Technology Features |

|---|---|---|---|---|---|

| Model A | Automatic | 120 | 99.5 | 5 | Smart Sensor, Remote Monitoring |

| Model B | Semi-Automatic | 80 | 98.7 | 4 | User-Friendly Interface, Quick Changeover |

| Model C | Fully Automatic | 150 | 99.2 | 6 | AI Optimization, IoT Connectivity |

| Model D | Gravity Fill | 70 | 97.5 | 3 | Simple Design, Minimal Maintenance |

| Model E | Piston Fill | 100 | 98.9 | 5.5 | Versatile Sizes, High Viscosity Handling |

| Model F | Auger Fill | 120 | 99.8 | 7 | Precision Dispensing, Easy Calibration |

| Model G | Vacuum Fill | 90 | 98.0 | 4.5 | Sealed Environment, Dust-Free Operation |

| Model H | Flow Meter Fill | 130 | 99.3 | 6.2 | Real-Time Monitoring, Energy Efficient |

| Model I | Multi-Head Fill | 200 | 99.7 | 8 | High-Speed, Compact Design |

| Model J | Linear Fill | 160 | 99.1 | 5.8 | Modular Design, Quick Setup |

When choosing a high-performance filling machine in 2025, there are several key features that should be prioritized to ensure maximum efficiency and reliability. Firstly, consider the machine's speed and versatility. The ability to adapt to various container shapes and sizes, along with rapid filling speeds, can significantly enhance productivity. Look for machines equipped with advanced automation features that facilitate seamless integration into existing production lines, minimizing downtime and operational hindrances.

Another crucial aspect is precision in filling volume. High-performance machines utilize sophisticated technology to maintain accuracy, preventing overfilling or underfilling, which not only conserves resources but also ensures compliance with industry standards. Additionally, hygiene and ease of cleaning are paramount in the pharmaceutical and food sectors. Machines designed with smooth surfaces and easy disassembly enable rapid cleaning and maintenance, which is essential in meeting stringent regulatory requirements. Investing in these features will lead to enhanced overall performance and efficiency in filling operations.

When selecting the best filling machine for your production line, understanding the advantages and limitations of different types is crucial. According to a report by MarketsandMarkets, the global filling machines market is projected to reach USD 4.59 billion by 2025, with a significant emphasis on automatic and semi-automatic machines for improved efficiency. For instance, gravity fillers are often favored for their simplicity and cost-effectiveness, making them ideal for thicker liquids, while vacuum fillers ensure precision in the filling process for more viscous products.

Tip: When evaluating filling machines, consider conducting a thorough comparison of machine specifications, including speed, accuracy, and compatibility with your product type. This can prevent potential operational bottlenecks and ensure you choose a machine that aligns with your production needs.

Moreover, the introduction of advanced technologies, such as servo-driven filling systems, has transformed the industry. These systems offer unparalleled accuracy, reducing product waste by up to 30%, as noted in a recent study from The International Journal of Advanced Manufacturing Technology. This shift not only enhances performance but also allows for a better return on investment in the long term.

Tip: Always factor in your packaging speed and product characteristics when choosing a filling machine. An appropriate machine that matches your operational pace will significantly boost your overall productivity and reduce downtime.

As industries shift towards more sustainable practices, the design and functionality of filling machines are evolving to meet these demands. Modern filling equipment is now being engineered with eco-friendly materials and energy-efficient processes that minimize waste and reduce the carbon footprint. For example, innovative technologies such as precise metering systems and programmable controls not only enhance accuracy but also significantly lower the energy consumption associated with traditional filling methods.

Moreover, manufacturers are increasingly prioritizing the use of recyclable and biodegradable components in their filling machinery. This trend not only aligns with global sustainability goals but also caters to the growing consumer demand for environmentally responsible products. Advanced filling machines are now equipped with features such as closed-loop systems and waste-reducing designs, which streamline operations and promote a circular economy.

As businesses embrace these sustainable filling solutions, they not only improve their operational efficiencies but also contribute positively to environmental preservation, making a notable impact in the packaging industry.

As manufacturers strive for efficiency in their production lines, the choice of filling machines becomes critical. User experiences reveal that brands like BottlingTech and FillFast have significantly enhanced their operations. BottlingTech’s precision fillers have been praised for their reliability and minimal downtime, allowing companies to meet tight production schedules without compromising quality. Users report improved consistency in fill levels, which has positively impacted their bottom line.

Furthermore, FillFast’s versatile filling systems have garnered attention for their adaptability across various product types. Users shared success stories about how their machines seamlessly transitioned from filling liquids to pastes, accommodating fluctuating market demands. This flexibility has not only increased productivity but also reduced the need for multiple machines, providing significant savings in both space and investment. The integration of advanced technology in these brands underscores the importance of user feedback in refining product designs, ultimately driving greater performance in filling operations.

Accutek Packaging Equipment Companies, Inc. stands as one of the premier privately owned packaging machinery manufacturers in the United States.

Sign up for all the news about our latest arrivals