In today's fast-paced food industry, the significance of a reliable sealing machine for food packaging cannot be overstated. As consumer preferences shift towards convenience and prolonged shelf life, the demand for efficient packaging solutions has surged. According to a recent report by the Future Market Insights, the global food packaging market is expected to reach USD 600 billion by 2024, with a notable emphasis on sustainability and safety. A sealing machine for food packaging plays a vital role in ensuring that food products remain fresh, safe, and appealing to consumers, while also reducing waste and extending shelf life.

Moreover, as food safety regulations become increasingly stringent across various regions, manufacturers are turning to advanced sealing technologies to comply with these standards. The Packaging Machinery Manufacturers Institute (PMMI) indicates that 65% of food producers are investing in advanced packaging machinery, including sealing machines, to enhance operational efficiency and meet consumer expectations. This growing trend underscores the importance of adopting state-of-the-art sealing solutions, which not only optimize production processes but also significantly contribute to brand reputation and consumer trust. In conclusion, the use of a sealing machine for food packaging is no longer a mere option but a necessity for food businesses aiming to thrive in today’s competitive market.

In the competitive landscape of today's market, food packaging plays a critical role in both preserving product quality and enhancing consumer appeal. As consumers become increasingly health-conscious and environmentally aware, effective packaging serves not just as a barrier against contamination, but also as a vital communication tool. Packaging must effectively convey information about freshness, ingredients, and sustainability, influencing purchasing decisions and fostering brand loyalty.

Moreover, modern market dynamics require businesses to adapt to evolving consumer preferences and demands for convenience. Innovative packaging solutions, including vacuum sealing and modified atmosphere packaging, help extend shelf life and maintain the integrity of perishable goods. This is particularly important in a fast-paced, global market where products travel long distances, and the risk of spoilage increases. A reliable sealing machine becomes essential for ensuring that food products reach consumers in optimal condition, reflecting a commitment to quality and safety that is increasingly valued by today's discerning customers.

| Dimension | Importance | Impact on Market |

|---|---|---|

| Food Safety | Prevents contamination and spoilage | Increases consumer trust in products |

| Product Freshness | Extends shelf life of food items | Reduces food waste and loss |

| Branding | Enhances visual appeal of packaging | Differentiates products in competitive market |

| Cost Efficiency | Reduces packaging material waste | Optimizes production processes |

| Regulatory Compliance | Meets food packaging regulations | Avoids legal issues and penalties |

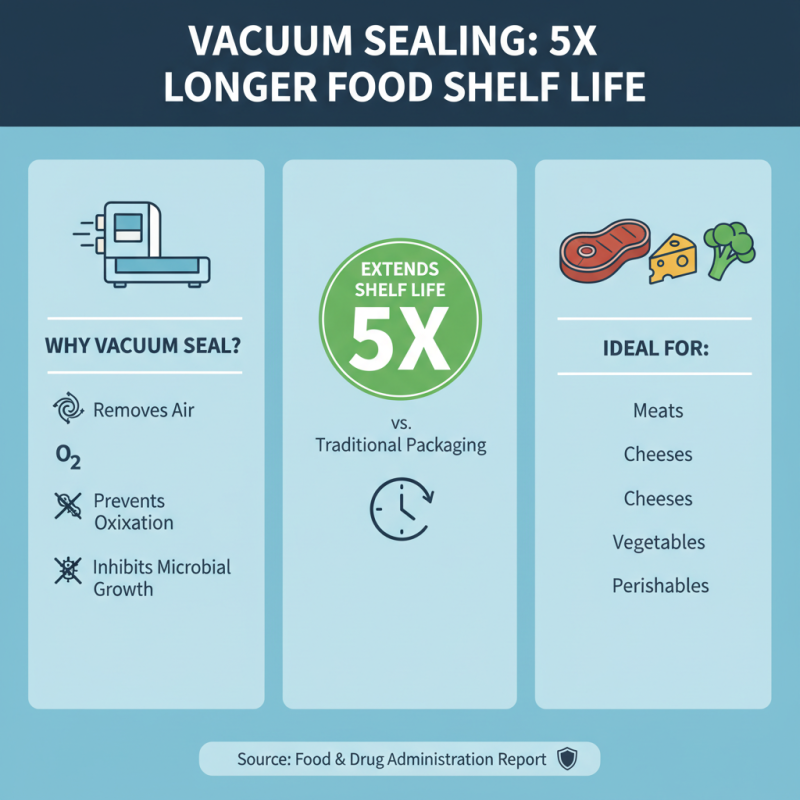

When it comes to food packaging, selecting the right sealing machine is crucial in ensuring product safety and extending shelf life. Among the various types of sealing machines available in the market, vacuum sealers stand out due to their ability to remove air from the packaging, thus preventing oxidation and microbial growth. According to a report by the Food and Drug Administration, proper vacuum sealing can increase the shelf life of packaged food by as much as 5 times compared to traditional packaging methods. This is particularly important for perishable items such as meats, cheeses, and vegetables, where maintaining freshness is essential.

In addition to vacuum sealers, heat sealers are another popular choice for food packaging. These machines apply heat to a plastic bag or film, creating a tight seal that keeps food products secure and fresh. The global food packaging machinery market is projected to grow, with an anticipated increase in the heat sealing segment driven by advancements in technology. The Food Packaging Machinery Report indicates that the heat sealing equipment market is expected to reach $4 billion by 2025. This growth highlights the necessity for businesses to invest in efficient sealing machines that can accommodate varying food products while maintaining quality.

Choosing the right type of sealing machine not only meets safety compliance but also enhances branding and customer satisfaction by ensuring that food products remain in optimal condition from production to consumption. As the competition in the food industry intensifies, understanding the different sealing technologies becomes imperative for manufacturers aiming to thrive in today’s market.

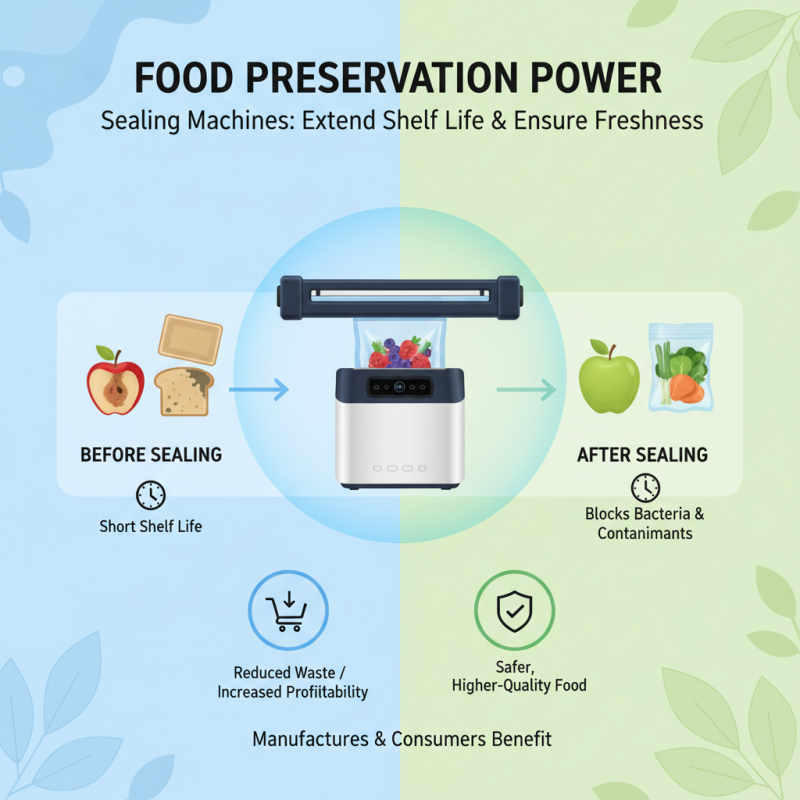

In today's competitive market, using sealing machines for food preservation has become essential for both manufacturers and consumers. One of the key benefits of these machines is their ability to significantly extend the shelf life of food products. By creating an airtight seal, these machines prevent the entry of harmful bacteria and contaminants, thereby maintaining the quality and freshness of the food for longer periods. This is particularly vital for perishable items, as it allows businesses to reduce waste and maximize profitability while ensuring that consumers receive safe and high-quality products.

Additionally, sealing machines enhance the overall presentation of food packaging. Well-sealed packages not only protect the contents but also convey a sense of professionalism and attention to detail. This can positively influence consumer perception and brand loyalty. Furthermore, modern sealing technologies often include options for vacuum sealing or gas flushing, which can help preserve the flavor, texture, and nutritional value of food. As consumers increasingly seek freshness and quality, utilizing sealing machines can provide a distinct competitive advantage in the food market, elevating both product viability and consumer satisfaction.

When selecting a sealing machine for food packaging, several factors are critical to ensuring efficiency and quality in your production process. One key consideration is the type of sealing technology that best suits your products. Heat sealing, for instance, is widely favored for its effectiveness in creating airtight seals, which is essential in maintaining food freshness and extending shelf life. According to a 2022 report by Market Research Future, the global food packaging machinery market is projected to reach $53 billion by 2027, driven significantly by advances in sealing technology that enhance product preservation.

Another important factor is the machine's production capacity. Businesses need to assess their volume requirements and choose a sealing machine that can handle their output without compromising speed or quality. A study by Statista highlighted that food packaging producers are increasingly investing in high-speed sealing solutions, anticipating a shift towards automation driven by both efficiency and labor cost considerations. Moreover, durability and maintenance are vital; machines built from high-quality materials will reduce downtime and service costs, making them a more economical choice in the long run. By evaluating these factors, businesses can select a sealing machine that aligns with their operational needs and market demands.

In today's rapidly evolving food industry, advancements in packaging technology are crucial for maintaining quality and safety while meeting consumer demands. The role of sealing machines has become increasingly significant as they cater to the need for efficient, reliable, and hygienic packaging solutions. With innovations such as vacuum sealing and modified atmosphere packaging, these machines are designed to extend product shelf life and preserve nutritional value, making them essential for food manufacturers striving to enhance their market competitiveness.

Additionally, the trend toward sustainability in food packaging cannot be overlooked. Many companies are now focusing on eco-friendly materials and processes to reduce environmental impact. Sealing machines that accommodate biodegradable and recyclable materials play a pivotal role in this shift, enabling companies to meet sustainability goals without compromising packaging integrity. Furthermore, automation and smart technologies are making sealing machines more sophisticated, allowing for higher productivity and better quality control, which are vital in an industry where safety and consumer trust are paramount.

Accutek Packaging Equipment Companies, Inc. stands as one of the premier privately owned packaging machinery manufacturers in the United States.

Sign up for all the news about our latest arrivals