In today's fast-paced industrial landscape, the drive for efficiency has led to significant advancements in packaging solutions. Among these innovations, the automatic packing machine stands out as a transformative force that is reshaping the packaging sector. According to a recent report by Research and Markets, the global automatic packing machine market is projected to reach $45 billion by 2025, growing at a compound annual growth rate (CAGR) of 5.4%. This surge is driven by the increasing demand for high-speed packing and the need for enhanced accuracy and reliability in packaging operations.

Industry expert Dr. Linda Petters, a prominent figure in packaging technology, notes, "The automatic packing machine not only streamlines the packing process but also significantly reduces downtime and human error." This sentiment is echoed across various sectors, where businesses are recognizing the cost-saving benefits and improved productivity that these machines offer. As companies continue to seek innovative solutions to meet changing consumer demands and enhance operational efficiency, the adoption of automatic packing machines is expected to accelerate, revolutionizing how products are packaged and distributed. In this article, we will explore the pivotal role of automatic packing machines in modern packaging solutions, highlighting their impact on industry performance and future trends.

The rise of automatic packing machines in the packaging industry is a transformative trend, significantly enhancing efficiency across various sectors. The global case packing machines market, estimated at USD 1.07 billion in 2024, is projected to reach USD 1.74 billion by 2033, reflecting a robust growth rate. This surge indicates that manufacturers are increasingly adopting automated solutions to streamline their processes, reduce labor costs, and improve output quality.

Furthermore, the global packaging machinery market is set to reach USD 100.6 billion by 2035, indicating a healthy CAGR of 4.5%. Such growth is predominantly driven by innovations in automatic packing technologies that cater to the rising demand for efficient, precise, and flexible packaging solutions. For instance, the powder packing machine market alone is expected to surpass USD 3.1 billion by 2034, showcasing the burgeoning demand for automated packaging systems that address the needs of various industries, including food processing and pharmaceuticals. The continual advancement in technology positions automatic packing machines as key players in revolutionizing packaging operations.

The chart above illustrates the significant growth in the market for automatic packing machines from 2018 to 2023, demonstrating how technological advancements have transformed modern packaging solutions.

The landscape of packaging solutions is undergoing a significant transformation, largely driven by advancements in automatic packing machines. Key technologies, such as robotics, artificial intelligence (AI), and Internet of Things (IoT) integration, are enhancing operational efficiency and reducing labor costs. According to a report by Smithers Pira, the global packaging machinery market is projected to reach $65.5 billion by 2024, driven by the increasing demand for automation in production lines.

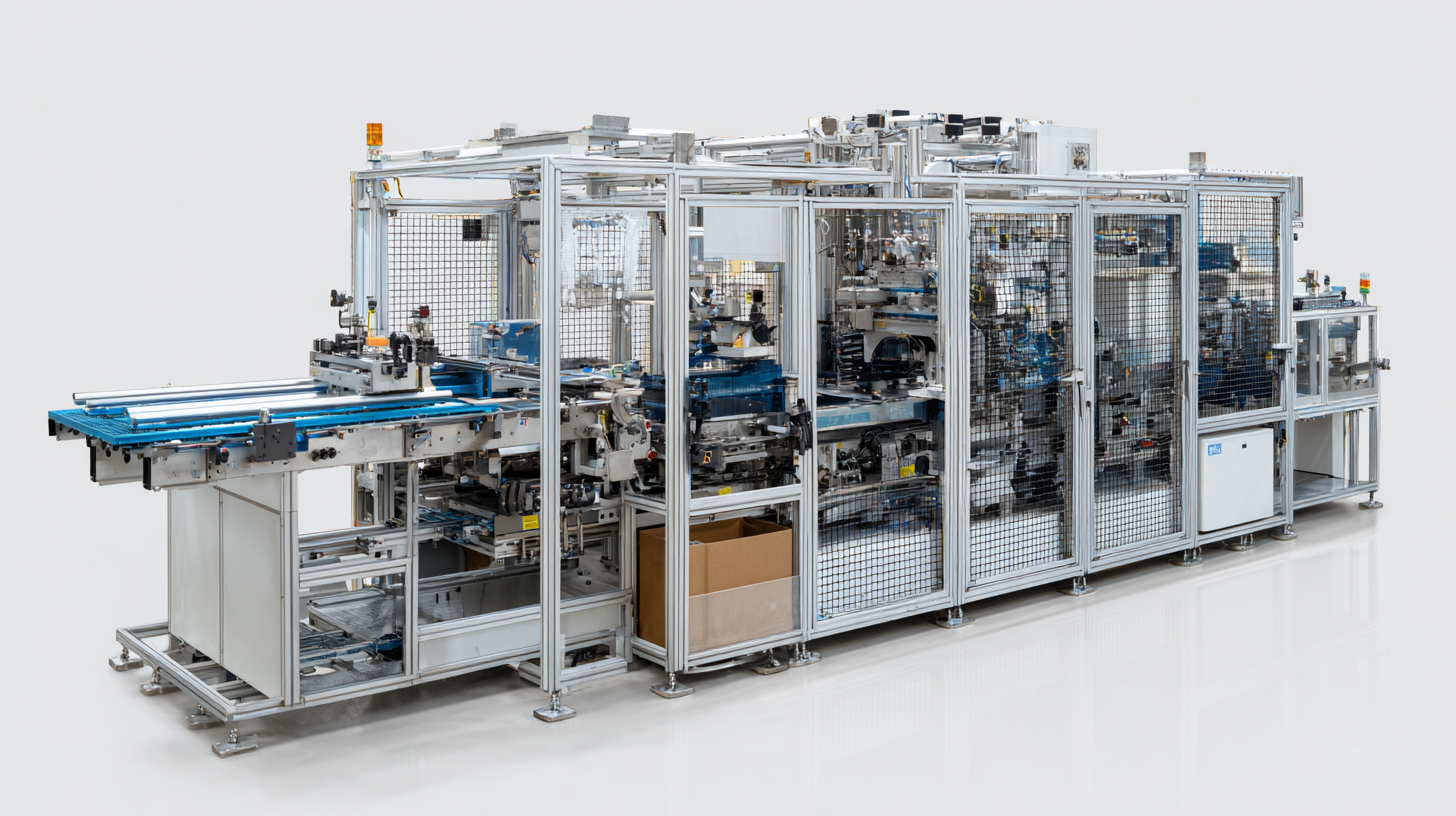

Robotics is revolutionizing the way products are packed, allowing for faster and more reliable operations. For instance, robotic arms equipped with advanced sensors can adjust to different package sizes and shapes, significantly decreasing setup time. Additionally, the integration of AI allows these machines to learn from production data and optimize packing strategies in real-time. The American Packaging Association estimates that automation can increase packing efficiency by as much as 30%, which plays a crucial role in meeting the demands of various industries, including food and beverage, pharmaceuticals, and e-commerce.

IoT technology further enhances the efficiency of packaging processes by enabling predictive maintenance and real-time monitoring of machinery. A recent study by Fortune Business Insights highlights that the IoT in packaging is expected to grow at a CAGR of 15.2% from 2021 to 2028, demonstrating the increasing reliance on connected devices to streamline packaging workflows. This convergence of automation and intelligence not only maximizes throughput but also ensures consistent product quality, making automatic packing machines an indispensable asset in modern packaging solutions.

In today's competitive landscape, the shift towards automation in packaging and warehousing is not merely a trend but a strategic necessity. The adoption of automatic packing machines is revolutionizing modern packaging solutions by driving significant cost savings and enhancing return on investment (ROI). Companies are increasingly recognizing that restructuring their operations with automated systems can lead to more streamlined processes, reduced labor costs, and improved accuracy, which are crucial in today’s high-demand environment.

Moreover, beyond the primary financial advantages, the integration of automation technologies fosters agility within supply chain operations. For instance, automated systems facilitate better inventory management and faster response times, ultimately contributing to the overall resilience of supply chains. Recent research emphasizes that businesses focused on warehouse automation are gaining a competitive edge by minimizing errors and optimizing throughput. As organizations continue to seek efficiency and effectiveness, the long-term financial benefits of automated systems will profoundly influence their operational strategies.

As industries increasingly recognize the importance of sustainability, automatic packing machines emerge as pivotal tools in creating eco-friendly packaging solutions. These machines not only enhance efficiency but also significantly reduce waste. By optimizing packing processes, they minimize material usage and promote the adoption of recyclable and biodegradable materials. This innovation enables companies to meet environmental regulations and consumer preferences for sustainable products.

Moreover, automation in packaging processes contributes to better resource management, furthering sustainability goals. Automatic packing machines can adjust to different product sizes and shapes, ensuring that packaging is tailored to individual products, which reduces excess material and enhances protection during transit. This precise packing capability not only lowers operational costs but also decreases the carbon footprint associated with production and distribution. Through these advancements, businesses are not only able to increase their efficiency but also commit to a more environmentally responsible approach, paving the way for a greener future in the packaging industry.

As the landscape of automatic packing technology continues to evolve, we stand on the brink of groundbreaking innovations that promise to reshape the packaging industry. The global high-end packaging equipment market is projected to reach a remarkable value of $981,256 million in 2024 and is expected to soar to $2,670,759 million by 2032. This staggering growth underscores the increasing demand for efficient, automated solutions that streamline packaging processes across various sectors.

Looking ahead, future innovations in automatic packing technology are set to harness the power of advanced robotics, artificial intelligence, and sustainable materials. Recent pilot projects, such as those utilizing reusable packaging systems, highlight the industry’s shift towards eco-friendly solutions that not only enhance operational efficiency but also address environmental concerns. As smart manufacturing becomes more prevalent, integrating IoT capabilities with packing machinery will further optimize production lines, reduce waste, and enhance overall supply chain management. The continuous drive for intelligent automation is not only transforming packaging but is also positioning businesses to meet the challenges of tomorrow’s market.

Accutek Packaging Equipment Companies, Inc. stands as one of the premier privately owned packaging machinery manufacturers in the United States.

Sign up for all the news about our latest arrivals