The food and beverage industry is undergoing a transformative shift, driven by advancements in technology, particularly the emergence of powder packaging machines. According to a report by MarketsandMarkets, the global food packaging market is projected to reach USD 500 billion by 2025, with a significant contribution from powder packaging solutions. The increased demand for convenience, longer shelf life, and improved product integrity has led manufacturers to adopt highly efficient powder packaging machines. These machines not only enhance operational efficiency but also ensure high precision in the packaging process, significantly reducing waste and improving product quality. As consumers increasingly seek ready-to-eat and easy-to-prepare food options, the role of powder packaging machines becomes more critical, redefining the standards of safety and sustainability in food packaging. This article delves into how these innovative machines are revolutionizing the industry by streamlining production, optimizing supply chains, and responding to evolving consumer needs.

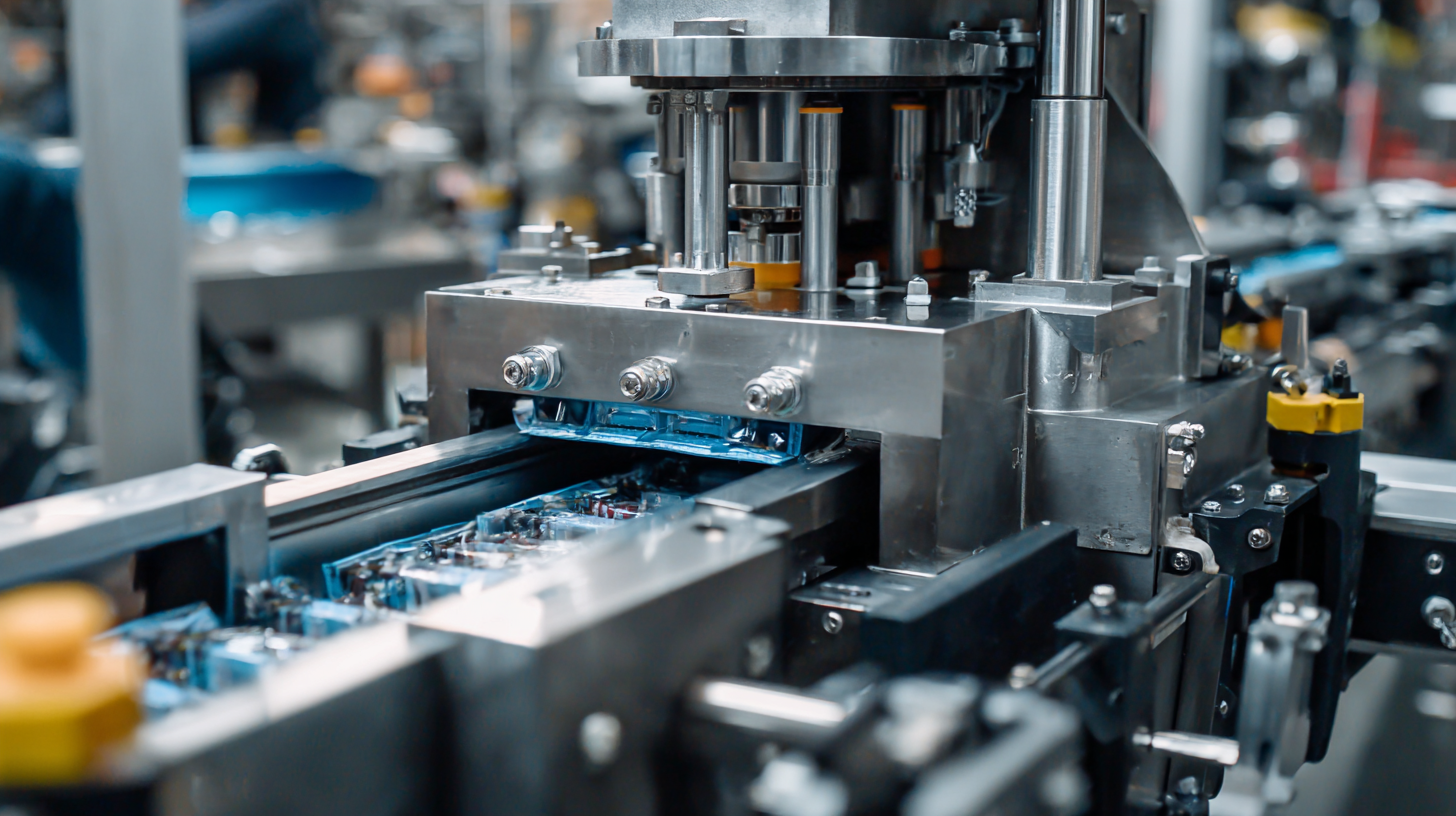

Powder packaging machines have significantly transformed the food and beverage industry by enhancing production efficiency across various sectors. These advanced machines streamline the packaging process, reducing the time and labor required to seal and distribute powdered products. By automating the packaging process, manufacturers can achieve higher output levels while minimizing human error, which is critical for maintaining product consistency and quality.

Furthermore, the precision of powder packaging machines ensures that each package is filled accurately, reducing waste and optimizing resource utilization. This efficiency not only leads to cost savings but also allows companies to respond more swiftly to market demands and consumer preferences. As a result, businesses can maintain their competitive edge while ensuring that their production lines operate smoothly and effectively. The integration of such technology is not just an upgrade; it's a vital evolution that shapes the future landscape of food and beverage packaging.

Advanced powder packaging solutions have emerged as a game-changer in the food and beverage industry, particularly in the quest to reduce food waste. According to a report by the Food and Agriculture Organization (FAO), approximately one-third of all food produced globally is wasted, contributing to a staggering economic loss of around $940 billion annually. By optimizing packaging processes, manufacturers can significantly extend the shelf life of powdered products, preventing spoilage and waste.

State-of-the-art powder packaging machines utilize vacuum sealing and modified atmosphere packaging to create an airtight environment that slows down oxidation and moisture absorption. For instance, a study published in the Journal of Food Science indicated that products packaged with advanced techniques could experience a shelf life increase of up to 50%. Retailers benefit from this extended shelf life, as it allows them to carry a wider variety of products without the fear of rapid expiration, ultimately leading to lower overall waste and improved profitability.

As the industry continues to innovate, these advanced packaging solutions are not only enhancing product quality and safety but are also playing a crucial role in promoting sustainability efforts. By reducing food waste, companies are helping to lower their environmental footprint while simultaneously meeting consumer demand for fresher, longer-lasting products.

Innovative packaging designs play a crucial role in enhancing the consumer experience in the powdered products sector. As the food and beverage industry evolves, attracting and retaining customers becomes increasingly important. Eye-catching packaging not only grabs attention on the shelves but also communicates the brand’s values and nutritional benefits effectively. For instance, user-friendly designs that feature resealable openings or portion control mechanisms allow consumers to enjoy convenience while ensuring product freshness. This practical approach meets the demands of modern lifestyles, appealing particularly to busy consumers seeking efficiency without compromising quality.

Moreover, the impact of packaging extends beyond aesthetics; it significantly influences consumer perception and trust. Sustainable materials, clear labeling, and informative graphics can enhance credibility, fostering a connection between the brand and its customers. In an age where consumers prioritize health and environmental considerations, brands that embrace innovative packaging solutions that are eco-friendly and informative illustrate their commitment to both quality and social responsibility. This multidimensional approach to packaging not only enhances the user experience but also builds lasting loyalty and advocacy among consumers.

Powder packaging machines are not just enhancing efficiency in the food and beverage sector; they are also leading to significant cost savings and fostering sustainability within supply chains. According to a recent study by Smithers Pira, the global packaging machinery market is projected to reach $50 billion by 2026, with powder packaging solutions playing a significant role. These machines streamline operations by reducing labor costs and material waste, leading to an estimated 20% decrease in overall packaging expenses for manufacturers.

Powder packaging machines are not just enhancing efficiency in the food and beverage sector; they are also leading to significant cost savings and fostering sustainability within supply chains. According to a recent study by Smithers Pira, the global packaging machinery market is projected to reach $50 billion by 2026, with powder packaging solutions playing a significant role. These machines streamline operations by reducing labor costs and material waste, leading to an estimated 20% decrease in overall packaging expenses for manufacturers.

One of the most impactful advantages of powder packaging technology lies in its ability to minimize environmental footprints. Many modern machines utilize biodegradable materials and energy-efficient processes, aligning with the growing demand for sustainable practices. The World Economic Forum reported that adopting sustainable packaging solutions could potentially reduce global greenhouse gas emissions by up to 25% by 2030. As companies adapt to these changes, they not only appeal to eco-conscious consumers but also enjoy improved compliance with environmental regulations.

Tips: When selecting a powder packaging machine, prioritize those that offer energy-efficient features and use recyclable materials to enhance sustainability. Regular maintenance of these machines can also prolong their lifespan, further reducing waste and costs. Lastly, consider investing in automated solutions to optimize labor allocation and minimize human error in the packaging process.

The powder packaging segment within the food and beverage industry is set for substantial growth, driven by evolving consumer preferences and an increasing demand for convenience. Recent market insights forecast the global beetroot powder market to reach a value of USD 640.5 million by 2034, growing at a CAGR of 5.1%. This upward trend in the demand for powdered products reflects a broader shift towards health-focused ingredients that align with consumers' growing awareness of nutrition and wellness.

In parallel, the composite cans market is also showing promise, with a projected value surpassing USD 5.1 billion in 2024, and a similar growth rate expected in the coming decade. This expansion is largely attributed to innovations in packaging technologies that enhance product shelf-life and consumer accessibility. Similar patterns are observed across various packaging forms, including biodegradable materials and recycled options, revealing a significant transition in the industry aimed at sustainability and efficiency. As manufacturers adapt to these trends, the food and beverage sector is poised for a transformative journey that prioritizes both quality and eco-friendliness in powder packaging solutions.

Accutek Packaging Equipment Companies, Inc. stands as one of the premier privately owned packaging machinery manufacturers in the United States.

Sign up for all the news about our latest arrivals