In today's fast-paced manufacturing landscape, the efficiency of your industrial vacuum sealer machine can significantly impact overall production costs and product quality. According to recent industry reports, companies that optimize their vacuum sealing processes can reduce packaging costs by up to 20% while increasing product shelf life by an average of 50%. This is particularly crucial in food processing, where maintaining freshness is paramount; studies show that improper sealing can lead to spoilage and substantial financial losses. As the global market for vacuum sealing is projected to reach over $6 billion by 2025, enhancing the performance of your industrial vacuum sealer machine is more critical than ever. In this guide, we will explore key strategies to maximize the efficiency and longevity of your sealing equipment, ensuring that you stay competitive in an ever-evolving market.

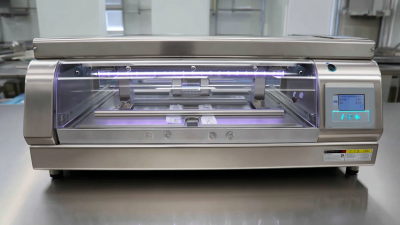

Understanding the key components of your industrial vacuum sealer is essential for optimizing its efficiency. The sealing mechanism, often the heart of the machine, determines the integrity and durability of the vacuum seal. It's crucial to choose seals that are suited for your specific application, as this impacts not only performance but also long-term reliability. Recent insights suggest that leveraging advanced sealing technologies, like robotic sealing systems, can enhance precision and consistency, leading to better outcomes in food storage and packaging.

Additionally, factors affecting seal integrity are paramount to consider. The materials used in heat sealing, for example, can greatly influence how well a package holds up under varying conditions. An in-depth understanding of these materials, alongside regular maintenance of the sealing equipment, will prevent costly errors and ensure high-quality results. As the vacuum sealing machine market continues to grow, keeping abreast of the latest advancements and market predictions helps businesses stay competitive. Adopting best practices in machine selection and maintenance will not only boost operational efficiency but also contribute to overall product safety and quality.

Maintaining optimal vacuum levels is crucial for the efficient operation of industrial vacuum sealers. According to a report from the Vacuum Packaging Association, proper vacuum sealing can extend the shelf life of products by up to 400%, significantly reducing spoilage and waste. However, achieving the right vacuum level is not just about settings; it also involves understanding the materials being sealed and the environment in which the machine operates.

To maintain optimal vacuum levels, regularly check and calibrate your vacuum gauge. A small deviation from the ideal vacuum level can lead to compromised seals, resulting in product contamination or spoilage. Additionally, ensure that your sealing surfaces are clean and free from debris. This not only improves sealing effectiveness but also prolongs the life of your machine.

Tip: Perform a vacuum pull test periodically, using test packages to ensure your machine is achieving the desired level of vacuum. This proactive approach can help you identify potential issues before they impact productivity. Implementing regular maintenance schedules will also contribute to consistent sealing quality and overall operational efficiency.

| Parameter | Optimal Value | Impact on Sealing | Frequency of Check |

|---|---|---|---|

| Vacuum Level (inHg) | 28 - 30 inHg | Ensures proper seal integrity | Daily |

| Seal Temperature (°C) | 160 - 180 °C | Affects seal strength and durability | Weekly |

| Time to Vacuum (seconds) | 25 - 45 seconds | Crucial for achieving proper evacuation | Daily |

| Seal Width (mm) | 8 - 12 mm | Influences the package's protection | Monthly |

| Maintenance Schedule (hours) | Every 200 operating hours | Prevents breakdowns and prolongs machine life | As needed |

Regular maintenance of your industrial vacuum sealer machine is essential for ensuring longevity and optimal performance. According to a report by the Food Processing Industry Association, poorly maintained sealing machines can reduce efficiency by up to 30%, leading to increased operational costs. Routine checks on the machine’s seals, vacuum pumps, and filter systems are crucial. For instance, replacing worn sealing elements can prevent air leaks, which may compromise the integrity of vacuum-sealed products.

Tip: Schedule weekly inspections to assess the condition of the vacuum seals and perform necessary adjustments. This practice not only prolongs the life of the machine but also enhances the quality of the sealed products.

Moreover, keeping the machine clean and free from debris is equally important. The Institute of Packaging Professionals suggests that regular cleaning reduces the risk of contamination and malfunction. Investing in high-quality replacement parts and lubricants can also improve performance while reducing wear and tear.

Tip: Implement a bi-monthly deep-cleaning routine where you dismantle and clean each component, ensuring that all parts move freely and efficiently. This attention to detail pays off by maintaining the machine's reliability and performance.

When optimizing the efficiency of your industrial vacuum sealer machine, choosing the right packaging materials is essential. The selection of materials can significantly impact not only the functionality and durability of the seal but also the sustainability of the packaging process. Recently, industry leaders have been exploring various practices to enhance sustainability in packaging, such as marking high-grade products for better recycling. This reflects a growing awareness of the environmental impacts of packaging choices.

In the quest for sustainable packaging, guidelines are vital in ensuring that the right materials are used throughout the product lifecycle. For instance, incorporating eco-friendly packaging options and durable materials can minimize waste and improve product protection. Additionally, engaging with sustainability indices can help businesses assess the impact of their packaging choices while complying with emerging regulations. The emphasis on green manufacturing—starting from design and extending through the entire lifecycle—can lead to better brand reputation and customer loyalty, aligning business practices with environmental stewardship.

When operating an industrial vacuum sealer machine, efficiency can often be undermined by common issues that arise during its use. One prevalent problem is insufficient vacuum power, which may result from a clogged filter or worn seals. Regularly inspecting and replacing these components can significantly enhance performance. Additionally, ensuring that the vacuum chamber is properly maintained and cleaned will prevent residue buildup, allowing the machine to operate at its peak capabilities.

Another issue that can hinder efficiency is improper sealing. This can occur if the sealing bars are misaligned or the temperature settings are incorrect. It’s essential to calibrate these settings based on the materials being sealed to ensure a proper bond. Regular checks for wear on sealing elements also contribute to consistent results. By addressing these common pitfalls through regular maintenance and appropriate settings adjustments, you can optimize the efficiency of your vacuum sealer and achieve better production outcomes.

Accutek Packaging Equipment Companies, Inc. stands as one of the premier privately owned packaging machinery manufacturers in the United States.

Sign up for all the news about our latest arrivals