In today's fast-paced and diverse industrial landscape, the versatility of the commercial vacuum packing machine has emerged as a game changer across various sectors. From food preservation to pharmaceuticals, these machines have transcended their traditional uses, showcasing innovative applications that enhance efficiency, reduce waste, and improve product longevity. As businesses increasingly focus on sustainability and cost-effective solutions, the adoption of commercial vacuum packing machines has skyrocketed, allowing for not only better storage solutions but also more effective packaging processes. This blog will explore the transformative impact of these machines across different industries, highlighting top innovative uses that illustrate their pivotal role in modern operations. Join us as we delve into the future of vacuum packing technology and its implications for businesses seeking a competitive edge.

As we advance into 2025, the food preservation industry is set to witness transformative innovations driven by vacuum packing machines. These machines are not just crucial for extending shelf life; they are also enhancing food quality and safety. According to a recent market report, the global vacuum packing machine market size is projected to reach $3.5 billion by 2025, growing at a CAGR of 6.3%. This growth is attributed to the increased demand for processed and packaged foods, spurred by changing consumer lifestyles and a focus on convenience.

One innovative application of vacuum packing machines is in sous vide cooking, where food is vacuum sealed and cooked in a water bath at controlled temperatures. This method not only preserves the nutrients but also enhances flavor, making it increasingly popular among both professional chefs and home cooks. Furthermore, vacuum packing prevents freezer burn and oxidation, ensuring that food maintains its quality longer compared to traditional storage methods.

One innovative application of vacuum packing machines is in sous vide cooking, where food is vacuum sealed and cooked in a water bath at controlled temperatures. This method not only preserves the nutrients but also enhances flavor, making it increasingly popular among both professional chefs and home cooks. Furthermore, vacuum packing prevents freezer burn and oxidation, ensuring that food maintains its quality longer compared to traditional storage methods.

Tips: When using vacuum packing for food preservation, ensure that you properly seal each bag to prevent air pockets, which can lead to spoilage. Additionally, use high-quality bags designed for vacuum sealing to ensure durability and effectiveness. Regularly check your vacuum packing machine for any maintenance needs to ensure that it operates at peak efficiency.

In the rapidly evolving market of commercial vacuum packing machines, businesses are continually seeking the best solutions to enhance efficiency and preserve product quality. According to a report by Markets and Markets, the vacuum packaging industry is projected to grow from USD 28.8 billion in 2022 to USD 36.7 billion by 2027, driven by the increasing demand for packaged food and the rising awareness of food safety. This trend underscores the importance of selecting the right vacuum packing machines, as they significantly impact operational workflows and product integrity across various sectors, including food, pharmaceuticals, and electronics.

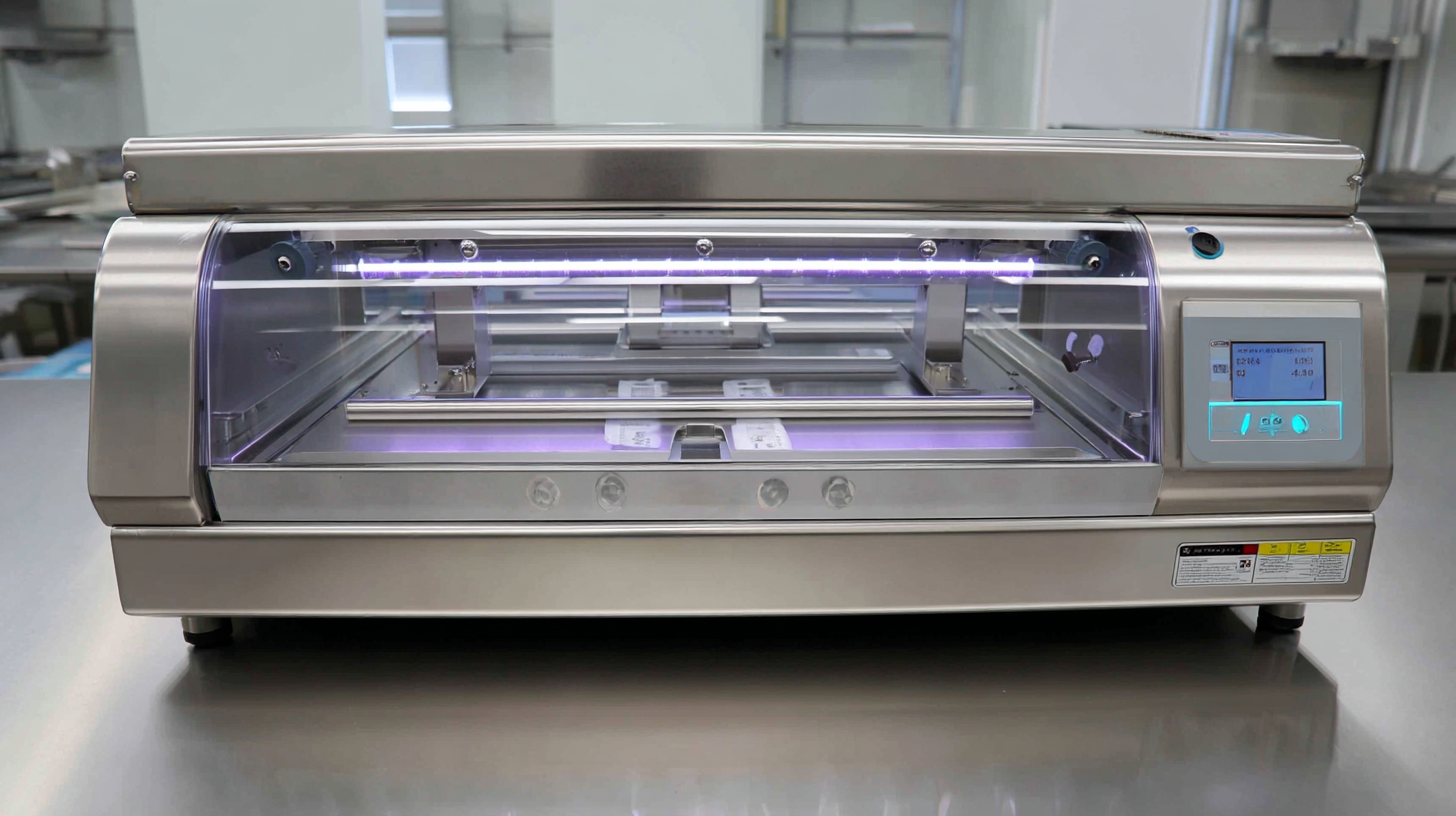

To help businesses choose the most suitable equipment, we conducted a comparative review of leading commercial vacuum packing machines available today. Notable models such as the Busch Veloce and the Multivac C-Series stand out for their advanced features, efficiency, and reliability. The Busch Veloce offers a unique vacuum flow control technology that reduces processing time by up to 30%, while the Multivac C-Series showcases a user-friendly interface combined with high throughput capabilities, making it a favorite among mid-sized food manufacturers. Such features are vital in meeting the growing consumer demand for high-quality, shelf-stable products without compromising freshness.

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Vacuum Pressure (in Hg) | 26 | 28 | 25 |

| Chamber Size (in inches) | 18 x 14 | 20 x 16 | 16 x 12 |

| Power (Watts) | 1100 | 1200 | 900 |

| Seal Bar Width (in inches) | 12 | 14 | 10 |

| Weight (lbs) | 60 | 70 | 55 |

| Applications | Food Packaging | Medical Supplies | Electronics |

As we approach 2025, the vacuum packing technology landscape is witnessing significant innovation, driven by advancements in automation, sustainability, and user-friendly designs.

According to a report by MarketsandMarkets, the global vacuum packaging market is projected to reach $35.5 billion by 2025, with a CAGR of 5.5% from 2020 to 2025.

This growth is largely attributed to the increased demand for packaged food, especially in the foodservice industry, where efficient preservation methods are crucial for maintaining product quality and shelf life.

One emerging trend is the integration of smart technology into vacuum packing machines.

These devices now come equipped with advanced software that monitors the packing process in real-time, ensuring that vacuum levels are optimized for freshness.

Furthermore, manufacturers are focusing on eco-friendly materials that are both more sustainable and capable of providing superior barrier protection against moisture and contaminants.

A notable example is the use of biodegradable films in conjunction with vacuum packing, appealing to environmentally conscious consumers.

Tips for Optimization: When selecting a vacuum packing machine, prioritize models with adjustable vacuum settings and sealing capabilities to accommodate a variety of products.

Additionally, investing in machines that support multi-layer packaging can enhance preservation and reduce waste for businesses looking to improve efficiency.

Tip for Maintenance: Regularly clean and inspect sealing bars and vacuum channels to prevent contamination and ensure consistent performance.

This simple maintenance can significantly extend the life of your commercial vacuum packing equipment.

In the dynamic world of e-commerce, vacuum packing has emerged as a game-changing technique for enhancing product safety and longevity. According to a report by Mordor Intelligence, the global vacuum packaging market is projected to reach USD 37.5 billion by 2027, driven by increased demand for extended shelf life and reduced food waste. With the ability to remove air and seal products tightly, vacuum packing not only preserves the freshness of food items but also protects them against environmental factors, which is crucial for maintaining customer satisfaction in e-commerce.

One of the key advantages of vacuum packing in e-commerce is its role in reducing spoilage and extending the usability of perishable goods. For instance, vacuum-sealed products can last up to five times longer than those stored conventionally, making them an ideal choice for online retailers looking to improve their delivery systems.

**Tips for E-commerce Businesses:**

1. Invest in high-quality vacuum packing machines to ensure the integrity of your products.

2. Clearly label vacuum-packed items to inform customers about shelf life and storage conditions.

3. Use sustainable vacuum packing materials to appeal to eco-conscious consumers, aligning your brand with modern sustainability trends.

As we move into 2025, vacuum packing technology is breaking free from its traditional associations with food preservation and storage. Industries such as healthcare, electronics, and textiles are beginning to leverage these machines for a myriad of innovative applications.

In healthcare, vacuum packing plays a crucial role in sterilizing medical instruments and packaging sensitive pharmaceuticals. By removing air and moisture, these packs ensure longer shelf-life and compliance with stringent safety standards, thus improving the reliability of critical healthcare systems.

The electronics industry is also embracing vacuum packing to protect delicate components from dust, moisture, and corrosion. Innovative materials and techniques allow manufacturers to package circuit boards and microchips in vacuum-sealed environments, maintaining their integrity during shipping and storage. Similarly, the textile industry is utilizing vacuum packing to compress garments, reducing storage space and shipping costs while preserving fabric quality and preventing mold growth.

The electronics industry is also embracing vacuum packing to protect delicate components from dust, moisture, and corrosion. Innovative materials and techniques allow manufacturers to package circuit boards and microchips in vacuum-sealed environments, maintaining their integrity during shipping and storage. Similarly, the textile industry is utilizing vacuum packing to compress garments, reducing storage space and shipping costs while preserving fabric quality and preventing mold growth.

These advancements not only streamline operations but also contribute to sustainability by minimizing waste and resource use across multiple sectors.

Accutek Packaging Equipment Companies, Inc. stands as one of the premier privately owned packaging machinery manufacturers in the United States.

Sign up for all the news about our latest arrivals