In the contemporary landscape of food preservation, the role of innovative packaging solutions has become increasingly vital. A significant contributor to this evolution is the sealing machine for food packaging, which enhances food longevity by effectively minimizing exposure to air and moisture. According to a report by Grand View Research, the global food packaging market is expected to reach $500 billion by 2025, driven in part by advancements in technology that improve shelf life and reduce food waste. Additionally, the Food and Agriculture Organization (FAO) highlights that nearly one-third of all food produced globally is lost or wasted, underscoring the critical need for effective preservation techniques.

By harnessing the power of advanced sealing machines, producers can not only extend the freshness of their products but also contribute to sustainable practices in the food industry, ultimately benefiting consumers and the environment alike.

Food longevity, or the shelf life of food products, is crucial in our modern consumption habits. As populations grow and urban lifestyles evolve, the demand for convenient and long-lasting food options has surged. Understanding the importance of food longevity goes beyond mere preservation; it relates to food safety, waste reduction, and economic efficiency. Extended shelf life means that consumers can enjoy their food products without the constant worry of spoilage, which is particularly important in busy households where meal planning is less predictable.

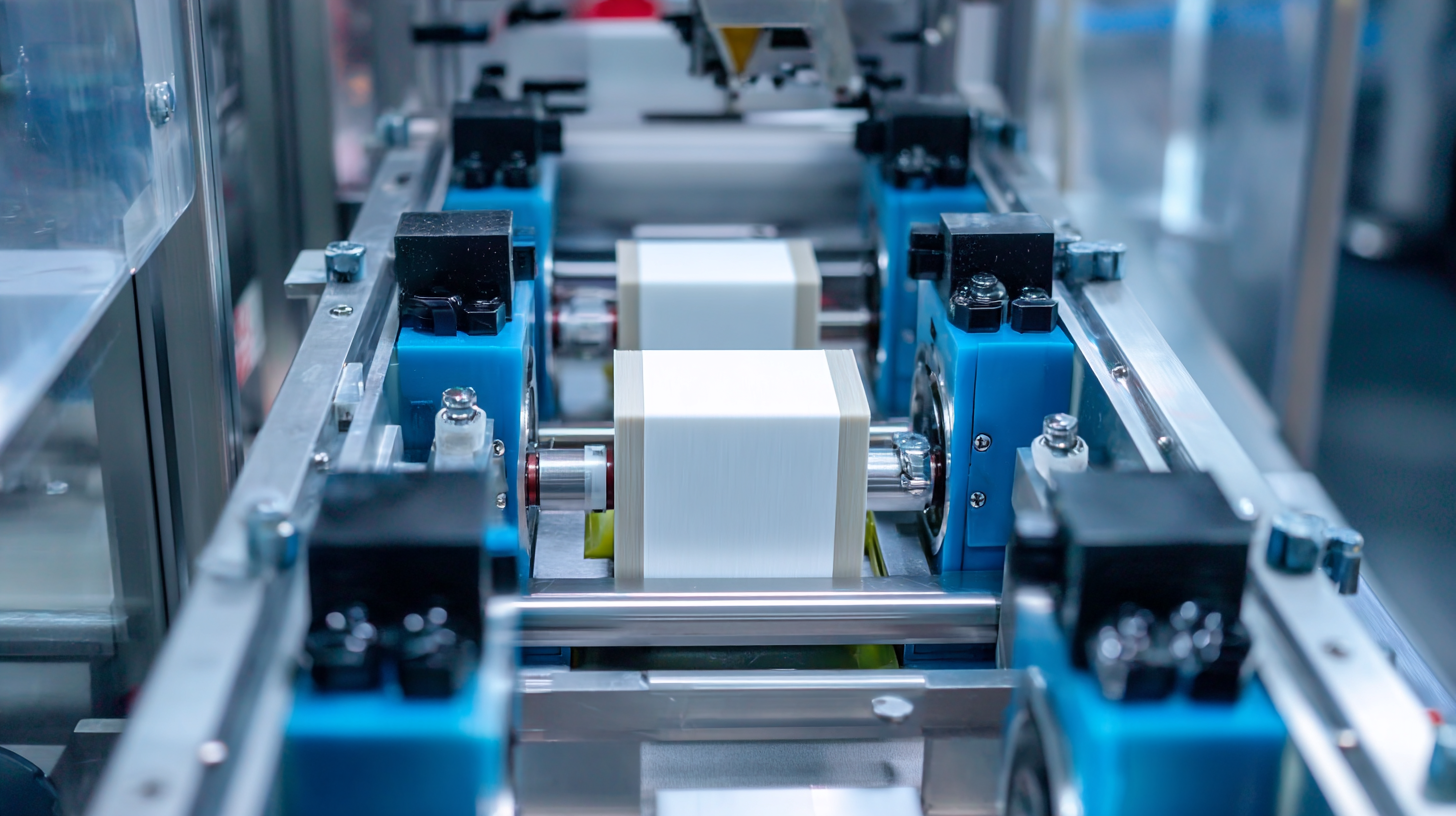

To achieve optimal food longevity, innovative techniques, including advanced food packaging, play a significant role. Utilizing the best sealing machines for food packaging ensures that products are adequately protected from environmental factors such as air and moisture, which can accelerate spoilage. By investing in high-quality sealing technology, manufacturers can extend the freshness of their offerings, ultimately benefiting both consumers and the environment by reducing food waste. This progressive approach to food preservation not only enhances individual health and safety but also contributes to a more sustainable food system in a rapidly changing world.

This chart illustrates the average shelf life (in days) of various food items packaged with innovative sealing techniques compared to traditional methods.

Sealing machines play a critical role in food preservation, significantly extending the shelf life of various products. According to a report by the Food Packaging Association, properly sealed food items can last up to three times longer compared to those that are inadequately packaged. This enhancement in longevity is primarily due to the reduction of exposure to air, moisture, and contaminants, which are common culprits in food spoilage. By utilizing state-of-the-art sealing machines, manufacturers can ensure airtight seals that inhibit the growth of bacteria and mold, ultimately maintaining the quality and safety of food products.

Sealing machines play a critical role in food preservation, significantly extending the shelf life of various products. According to a report by the Food Packaging Association, properly sealed food items can last up to three times longer compared to those that are inadequately packaged. This enhancement in longevity is primarily due to the reduction of exposure to air, moisture, and contaminants, which are common culprits in food spoilage. By utilizing state-of-the-art sealing machines, manufacturers can ensure airtight seals that inhibit the growth of bacteria and mold, ultimately maintaining the quality and safety of food products.

Moreover, advancements in sealing technology have led to the development of vacuum sealing and modified atmosphere packaging (MAP) techniques. Research from the Institute of Packaging Professionals indicates that vacuum sealing can reduce food spoilage rates by up to 50%, providing a cost-effective solution for both manufacturers and consumers alike. These innovations not only prolong freshness but also help in preserving the nutritional values of food items. As the demand for extended shelf life continues to rise, the role of high-quality sealing machines becomes increasingly vital in the food packaging industry, presenting an opportunity for businesses to enhance their product offerings and meet consumer needs effectively.

Effective food packaging solutions are crucial in today's fast-paced world, where food spoilage poses a significant challenge for both consumers and providers. Innovative techniques, such as vacuum sealing and modified atmosphere packaging (MAP), have emerged as powerful tools to extend food longevity. Vacuum sealing removes air around the food, which drastically reduces oxidation and bacterial growth, thereby preserving the freshness for a longer time. On the other hand, MAP replaces the air in the packaging with a gas mixture that slows down microbial growth and preserves the quality of the food.

Tips to Enhance Food Packaging:

When evaluating the best sealing machines for home and commercial use, several factors come into play. A quality sealing machine should ensure airtight seals, preserving food freshness and extending its shelf life. For home use, compact and user-friendly machines are ideal. These models often feature customizable settings for different bag thicknesses and types, making them versatile for various food items. Additionally, options like seal-only functions allow for greater flexibility when packaging delicate foods.

For commercial use, larger, high-capacity machines are necessary to handle increased volume without sacrificing quality. Models that offer double sealing options and vacuum features take food preservation to the next level. It’s crucial to consider machines that adhere to safety standards and offer durable materials, ensuring long-term reliability.

**Tips:** When choosing a sealing machine, look for one with a strong warranty and customer service support. Additionally, consider machines that include starter kits with bags or rolls, allowing instant use without the extra hassle of purchasing supplies separately. Lastly, reading customer reviews can provide valuable insights into performance and durability, guiding you to the best option for your needs.

| Sealing Machine Type | Best Use | Sealing Method | Vacuum Feature | Price Range |

|---|---|---|---|---|

| Manual Vacuum Sealer | Home Use | Vacuum & Seal | Yes | $30 - $50 |

| Automatic Vacuum Sealer | Home Use | One-Touch Operation | Yes | $100 - $200 |

| Commercial Chamber Sealer | Commercial Use | Chamber Vacuum | Yes | $800 - $1500 |

| Impulse Sealer | Home & Light Commercial | Heat Seal | No | $20 - $80 |

| Food Saver Sealer | Home Use | Vacuum & Seal | Yes | $50 - $100 |

Maximizing the shelf life of packaged foods is crucial in today's industry, where food waste remains a significant challenge. According to the Food and Agriculture Organization (FAO), around one-third of all food produced globally is wasted, amounting to approximately 1.3 billion tons annually. Implementing best practices in food packaging can dramatically reduce this waste. One effective technique is utilizing vacuum sealing, which removes air from the packaging. This method can extend the freshness of perishable items by up to five times compared to traditional packaging methods.

In addition to vacuum sealing, using high-quality sealing machines can enhance the longevity of food products. Machines equipped with advanced technology, such as heat sealing and inert gas flushing, are particularly effective. A report by Research and Markets indicates that the global food packaging market is projected to reach $1 trillion by 2024, underscoring the significance of investing in innovative sealing solutions. Furthermore, incorporating oxygen absorbers within the packaging can inhibit the growth of pathogens and spoilage microorganisms, subsequently prolonging the shelf life of various foods. These techniques not only preserve food quality but also contribute to a more sustainable food system by minimizing waste.

Accutek Packaging Equipment Companies, Inc. stands as one of the premier privately owned packaging machinery manufacturers in the United States.

Sign up for all the news about our latest arrivals