Choosing the right packaging equipment is a crucial decision that can significantly impact your business operations and overall success. In today's competitive market, effective packaging not only protects your products but also enhances your brand image and improves efficiency in production. With a multitude of options available, ranging from automated machines to manual tools, understanding your specific business needs becomes paramount.

Choosing the right packaging equipment is a crucial decision that can significantly impact your business operations and overall success. In today's competitive market, effective packaging not only protects your products but also enhances your brand image and improves efficiency in production. With a multitude of options available, ranging from automated machines to manual tools, understanding your specific business needs becomes paramount.

This guide aims to provide insights into the key factors to consider when selecting packaging equipment tailored to your requirements. By exploring aspects such as product type, production volume, budget constraints, and technological advancements, you will be better equipped to make informed decisions that align with your goals and enhance your packaging process.

Whether you're a small startup or an established enterprise, finding the right packaging equipment will play a vital role in streamlining operations and achieving long-term success.

When selecting the right packaging equipment for your business, understanding your specific requirements is crucial. A recent report from Smithers Pira estimates that the global packaging machinery market will reach $45 billion by 2027, driven by the growing demand for efficient and sustainable packaging solutions across various industries. Therefore, defining your business needs at the outset can lead to significant cost savings and enhanced productivity.

Consider factors such as the volume of products you need to package, the type of materials you use, and the desired speed of operation. A study from PMMI indicates that nearly 70% of manufacturers prioritize automation and flexibility in their packaging solutions, highlighting the importance of equipment that can adapt to changing product lines without extensive downtime. Additionally, embracing eco-friendly materials can not only meet consumer demands but also align with regulatory measures, making it essential to assess your sustainability goals when selecting your packaging equipment.

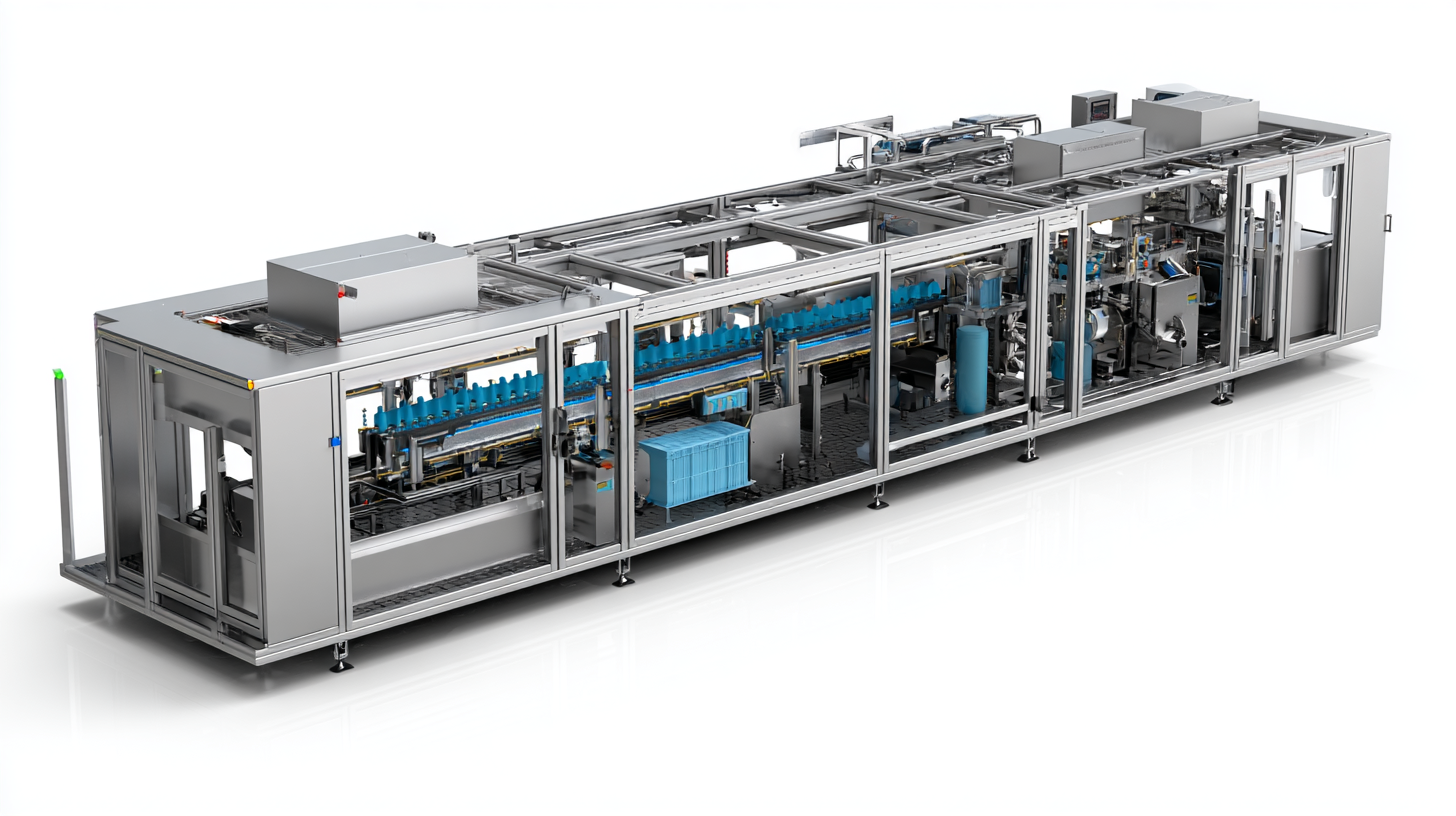

When evaluating different types of packaging equipment available, businesses must consider their unique needs, production volume, and the nature of the products being packaged. According to a report by MarketsandMarkets, the global packaging equipment market is projected to reach $60 billion by 2025, indicating a rapidly growing sector with numerous technological advancements. Companies can select from various types of packaging equipment, including automatic, semi-automatic, and manual machines, depending on their automation levels and budget constraints.

**Tips**: Before making a decision, assess the compatibility of packaging equipment with your existing production line. Look for equipment that allows for quick changeovers between different packaging formats, as versatility can significantly enhance operational efficiency. Additionally, consider energy-efficient models, as they can reduce operational costs and contribute to sustainability goals.

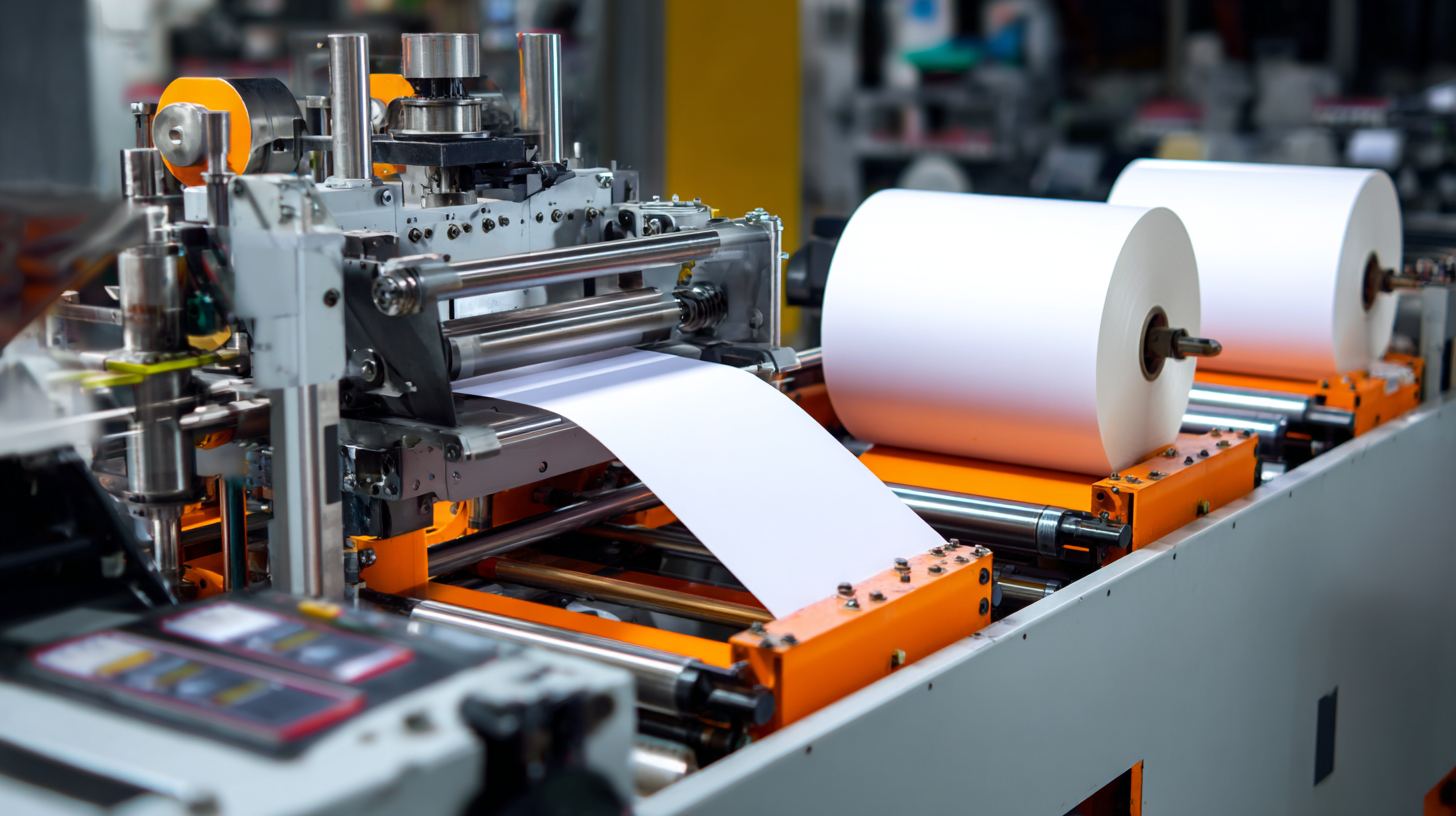

Another essential factor is the type of packaging material used. A 2022 study from Smithers Pira highlighted that flexible packaging is expected to grow at a rate of 4.3% annually, fueled by its lightweight nature and cost-effectiveness. Ensuring that your chosen equipment can handle the specific materials is crucial for maintaining packaging integrity and quality.

**Tips**: Research equipment manufacturers that specialize in your product type to gain insights into the latest innovations. Test the equipment in small batches to identify any potential challenges and to ensure that it meets your production expectations before making a significant investment.

| Equipment Type | Key Features | Best For | Cost Range |

|---|---|---|---|

| Semi-Automatic Case Packer | User-friendly controls, Adjustable settings | Low to medium volume packaging | $10,000 - $25,000 |

| Fully Automatic Wrapper | Speed, High throughput, Integration capabilities | High volume packaging | $30,000 - $100,000 |

| Shrink Tunnel | Consistent heat application, Compact design | All types of products that require shrink wrapping | $5,000 - $15,000 |

| Labeling Machine | Versatility, Speed, Accuracy | Any product requiring labeling | $3,000 - $20,000 |

| Vacuum Sealer | Preservation, Space-saving, Efficiency | Food packaging and perishable items | $1,000 - $5,000 |

When selecting packaging equipment for your business, understanding cost factors is crucial for making an informed decision. According to a recent report by Smithers Pira, the global packaging machinery market is projected to reach $50 billion by 2024, emphasizing the significance of choosing the right equipment in a competitive landscape. Costs can vary widely based on type, features, and customization levels, which directly affects your overall investment and operational efficiency.

Tip: Always conduct a cost-benefit analysis of the equipment you are considering. Identify your specific packaging needs and how they align with the machinery's capabilities. For instance, semi-automatic machines may offer a lower initial cost but can incur higher labor expenses over time. Conversely, investing in fully automatic systems might have a higher upfront cost but can significantly reduce labor costs in the long run.

Another crucial cost factor involves maintenance and operational expenses. A report from PMMI found that maintenance can account for approximately 2-5% of the total lifetime cost of packaging machinery. Regular maintenance not only prolongs equipment life but also prevents costly downtimes. Therefore, consider a machine that offers excellent service support and training, ensuring your team can operate it efficiently.

Tip: Factor in training costs during budgeting. Investing in proper training for employees can enhance machine utilization and reduce operational hiccups, ultimately leading to better profitability for your business.

When selecting packaging equipment for your business, it’s crucial to assess the scalability and flexibility of the machinery. Scalability refers to the equipment’s ability to adjust production volumes in response to changing demands. As your business grows, you may need to increase output without compromising efficiency or quality. Therefore, choosing machinery that can accommodate a range of production volumes is vital. Look for options that allow for rapid adjustments in speed and capacity, which can help mitigate downtime during transitions.

Flexibility is equally important, especially in today’s market where consumer preferences are constantly evolving. Equipment that can handle various packaging styles, sizes, and materials enables businesses to adapt quickly to new product launches or changes in design. This adaptability not only enhances operational efficiency but also ensures that companies can respond promptly to market trends. Investing in versatile machinery will ultimately save time and costs associated with acquiring new equipment for different products, providing a strategic advantage in a competitive landscape.

When selecting packaging equipment, it's essential to research the reputation of potential vendors. Start by examining customer reviews and testimonials, as these insights can reveal the quality of not only the equipment but also the vendor's reliability. Look for consistent feedback regarding the performance of their machines and how they have met the needs of various businesses. Reliable vendors often showcase case studies or provide references, allowing you to gauge how their products have functioned in real-world scenarios.

Support services provided by the vendor are equally crucial in the decision-making process. Ensure that the vendor offers comprehensive after-sales support, including installation, training, and maintenance services. A vendor with a strong support system will help minimize downtime and enhance the efficiency of your packaging operations. It's also wise to evaluate their response times and availability for service calls, as swift assistance can be critical in keeping your production line running smoothly. Prioritizing vendors with a proven track record in support services can make a significant difference in the long-term success of your packaging strategy.

Accutek Packaging Equipment Companies, Inc. stands as one of the premier privately owned packaging machinery manufacturers in the United States.

Sign up for all the news about our latest arrivals