In today's highly competitive food industry, maximizing shelf life and minimizing waste are critical for commercial success. According to a report by MarketsandMarkets, the global vacuum packaging market is projected to reach $32.3 billion by 2025, driven by the increasing demand for processed and packaged foods. A commercial vacuum packing machine acts as a vital tool for businesses looking to enhance their product longevity and maintain quality. By removing air from packaging, these machines prevent spoilage and extend freshness, making them essential for restaurants, food manufacturers, and retailers. In this guide, we will explore the five best commercial vacuum packing machines available on the market, helping you make an informed choice that aligns with your business needs.

When selecting a commercial vacuum packing machine, it’s essential to focus on specific features that can enhance your business operations. First and foremost, consider the sealing mechanism. A robust machine with high-quality seals ensures that your products remain fresh and free from air, which reduces spoilage. Look for machines that offer adjustable seal times and temperatures to accommodate various packaging materials.

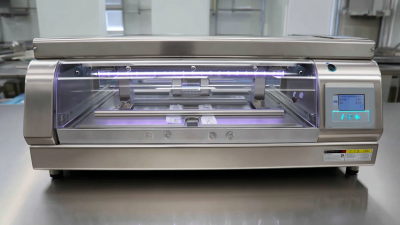

Another critical feature is the machine's capacity and size. Depending on your business scale, choose a machine that can handle the volume you require without compromising efficiency. A larger chamber allows for bulk packing, while a compact design may be suitable for smaller operations. Additionally, many commercial vacuum packing machines have built-in features such as automatic bag detection and moisture removal, which can significantly streamline your packaging process.

Tips: Regular maintenance of your vacuum packing machine can prolong its lifespan and maintain performance, so don’t overlook this aspect. Moreover, ensure the machine you choose is user-friendly, allowing your staff to operate it with minimal training. This will enhance productivity and reduce the chances of errors during the packing process.

When it comes to choosing the right vacuum packing machine for your business, it's essential to consider various brands that cater to different needs and budgets. Popular brands such as FoodSaver, VacMaster, and Weston each offer unique features that can enhance efficiency in your food packaging processes. FoodSaver machines are known for their user-friendly designs and compact sizes, making them ideal for small businesses and home kitchens. They offer versatile options for sealing both liquids and solids.

On the other hand, VacMaster machines are generally favored by larger operations due to their durability and heavy-duty capabilities. Their chamber vacuum sealers can handle high-volume tasks, making them perfect for restaurants or commercial kitchens. Weston, with its rugged construction, is an excellent choice for businesses that require both reliability and performance. Each brand has its strengths, so understanding your specific requirements—such as sealing speed, chamber size, and budget—will guide you in selecting the best vacuum packing machine for your business needs.

When it comes to vacuum packing machines for commercial use, businesses often find themselves faced with the dilemma of balancing cost against performance. High-end vacuum packing machines can be quite pricey, often exceeding $5,000. However, several cost-effective alternatives offer impressive capabilities without breaking the bank. According to a report by Freedonia Group, the demand for vacuum packaging in the food and beverage industry is expected to rise by 3.6% annually, reflecting the crucial role packaging plays in maintaining product quality and extending shelf life.

For small to medium-sized businesses, models such as the VacMaster VP215 and the Weston Pro-2300 demonstrate that affordability doesn’t necessarily mean sacrificing efficiency. These machines often come with robust features suitable for various packaging needs, including preserving food freshness and reducing waste. A study from Research and Markets indicates that effective vacuum sealing can reduce food spoilage by up to 50%, underscoring the importance of investing in a reliable vacuum packing solution, even at a lower price point. By integrating such machines into their operations, businesses can improve profitability while ensuring high standards of food safety and quality.

Innovative vacuum packing solutions have become essential for businesses across various industries, from food service to electronics. According to a report by Grand View Research, the global vacuum packing market is expected to reach USD 31.81 billion by 2025, with a CAGR of 3.3%. This growth reflects the increasing need for preserving product freshness, minimizing storage space, and reducing spoilage, particularly in sectors such as food safety and pharmaceutical logistics.

For businesses seeking to optimize their packaging processes, investing in a commercial vacuum packing machine is crucial. These machines not only extend the shelf life of products but also save on packaging materials and shipping costs. A key tip when selecting a vacuum packing machine is to assess the specific requirements of your business, including volume and product type. Machines like chamber and external vacuum sealers serve different purposes, so understanding your needs will enhance productivity and efficiency.

Furthermore, training staff on the proper use of these machines can significantly impact operational success. A study by the Food Packaging Association highlighted that companies implementing proper training saw a 20% increase in packaging efficiency. Emphasizing employee education on best practices ensures that your investment in vacuum packing technology translates to clearer product outcomes and reduced waste.

Maintaining your vacuum packing machine is essential for its longevity and optimal performance in a commercial setting. Regular cleaning is paramount; ensure that all food particles and debris are removed after each use. Pay special attention to the sealing area and the internal compartments, as remnants can affect the machine's efficiency and lead to potential malfunctions. Using a soft cloth and non-abrasive cleaners will help preserve the machine’s surfaces and internal components.

In addition to cleaning, it's vital to routinely check and replace the vacuum packing machine’s gaskets and sealing bars. Worn-out gaskets can lead to air leaks, compromising the vacuum seal and the quality of your packed products. Schedule regular inspections to ensure that all components are functioning correctly. Lubricate moving parts as recommended by the manufacturer to prevent wear and tear. By proactively addressing these maintenance tasks, you can extend the life of your vacuum packing machine and maximize its benefits for your business.

| Model | Chamber Size (inches) | Pump Power (HP) | Max Vacuum Pressure (mmHg) | Weight (lbs) | Price Range (USD) |

|---|---|---|---|---|---|

| Model A | 12 x 14 | 1.5 | 25 | 75 | $800 - $1,200 |

| Model B | 14 x 16 | 2.0 | 28 | 85 | $1,200 - $1,500 |

| Model C | 16 x 20 | 2.5 | 30 | 95 | $1,500 - $2,000 |

| Model D | 18 x 24 | 3.0 | 32 | 110 | $2,000 - $2,500 |

| Model E | 20 x 30 | 4.0 | 35 | 120 | $2,500 - $3,000 |

Accutek Packaging Equipment Companies, Inc. stands as one of the premier privately owned packaging machinery manufacturers in the United States.

Sign up for all the news about our latest arrivals