In the fast-paced landscape of modern manufacturing, optimizing efficiency is paramount, and one crucial element that has emerged in this regard is the powder packing machine. This innovative technology not only enhances the speed of production but also ensures precise measurement and consistency in packaging. As industries ranging from pharmaceuticals to food and cosmetics increasingly rely on powdered products, the need for advanced powder packing machines has never been greater.

This guide will explore the myriad benefits these machines offer, including increased productivity, reduced waste, and improved product quality. By delving into the operational features and advantages of powder packing machines, manufacturers can gain insights into how adopting this technology can lead to significant enhancements in their manufacturing processes, positioning them for greater success in an ever-competitive market.

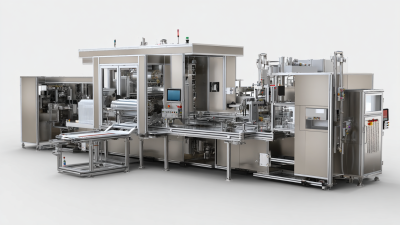

Advanced powder packing machines are transforming the landscape of modern manufacturing by enhancing efficiency and accuracy. These machines leverage high-tech features that optimize the packing process, ensuring consistent quality and reducing the risk of contamination. As industries increasingly demand precise measurements and speed, advanced packing solutions are equipped with innovative technology that integrates seamlessly into production lines, offering automation capabilities that minimize human error and streamline workflows.

Furthermore, the rise of powder-based additive manufacturing highlights the importance of advanced packing technology. This approach enables manufacturers to utilize powdered materials more effectively, optimizing resource use and enhancing product performance. The automatic powder forming machine market is projected to see significant growth, driven by the need for high-precision, efficient manufacturing processes. Such advancements not only improve operational productivity but also contribute to sustainability goals by reducing waste and optimizing material usage throughout the manufacturing cycle.

Advanced powder packing technology is revolutionizing manufacturing processes by enhancing efficiency and product quality. Key features of these machines include sophisticated powder characterization techniques, which have been shown to significantly influence flowability and dispersion. Recent studies highlight that factors such as particle size distribution and morphology can dramatically affect the dynamic behavior of powders during processes like additive manufacturing. For example, understanding the cohesive properties of powders can lead to improved performance in applications requiring precise powder handling.

Furthermore, innovative methods like enhanced centrifuge techniques provide deeper insights into powder characteristics, allowing for tailored solutions that meet specific manufacturing needs. These advancements not only streamline production but also optimize the use of advanced materials, making it easier to produce components with superior mechanical properties and microstructures.

**Tips:** When selecting advanced powder packing machines, prioritize models that offer real-time monitoring of powder flow and characteristics. This ensures better quality control and minimizes waste during production. Additionally, consider machines with versatile settings to accommodate different powder types, enhancing overall manufacturing flexibility.

In today's competitive manufacturing landscape, advanced powder packing machines have become vital for enhancing production efficiency and cost-effectiveness. According to a report by MarketsandMarkets, the global industrial packaging market is projected to reach $740 billion by 2026, driven by the increasing demand for efficient packaging solutions. These state-of-the-art machines can achieve packing speeds of up to 120 bags per minute, significantly reducing labor costs and minimizing packaging errors, which traditionally have a negative impact on production cycles.

Moreover, the integration of automation technologies in advanced powder packing machines allows manufacturers to optimize their operations. A study by Deloitte highlights that businesses implementing automation in their processes can boost productivity by 20-30%. This not only leads to faster turnaround times but also contributes to a decrease in material waste, further enhancing cost-effectiveness. With the ability to enhance precision and consistency in packaging, these machines play a crucial role in meeting the stringent quality standards that many industries require, ultimately leading to improved customer satisfaction and loyalty.

| Parameter | Traditional Packing Machines | Advanced Powder Packing Machines |

|---|---|---|

| Packing Speed (bags/min) | 20 | 50 |

| Accuracy (%) | 85 | 98 |

| Reduction in Labor Costs (%) | 30 | 60 |

| Equipment Downtime (hours/week) | 5 | 1 |

| Energy Consumption (kWh/bag) | 0.5 | 0.3 |

| Return on Investment (months) | 24 | 14 |

When comparing traditional and advanced powder packing methods, it's essential to highlight the significant differences in

efficiency and accuracy. Traditional methods often rely on manual labor and basic machinery, which can lead to inconsistent packing densities and increased waste. These methods may suffice for small-scale operations, but they struggle under the pressures of large-scale manufacturing, where precision and speed are critical.

On the other hand, advanced powder packing machines utilize state-of-the-art technology, including automated systems and sophisticated software. This enhances not only the speed of packing but also the accuracy, reducing the chance of errors that could lead to product loss. Additionally, modern machines often come with features such as real-time monitoring, which allows manufacturers to adjust parameters on-the-fly, further optimizing the packing process.

Tips: To ensure a smooth transition from traditional to advanced methods, consider conducting a pilot test with the new technology. This allows you to identify potential challenges and fine-tune the process before a full-scale implementation. Training employees on the new equipment is also crucial; invest in comprehensive training sessions to familiarize staff with the technology and maximize its benefits.

The future of powder packing machines is poised for significant advancements driven by automation and smart technology. As manufacturers seek increased efficiency and reduced labor costs, the integration of artificial intelligence and machine learning into packing processes will become commonplace. These innovations facilitate real-time monitoring and adjustments, ensuring optimal performance and minimal waste. Furthermore, smart sensors and data analytics can provide insights into machine operations, helping companies predict maintenance needs and enhance overall equipment effectiveness.

In addition to intelligent automation, there is a growing trend towards sustainable packing solutions. Manufacturers are increasingly exploring biodegradable and recyclable materials for packaging, aligning with global sustainability goals. Advanced powder packing machines will likely incorporate features that allow for quick adjustments to accommodate different types of eco-friendly packaging, thereby minimizing environmental impact while maintaining product integrity. As the industry evolves, these innovations will not only improve operational efficiency but also support responsible manufacturing practices, paving the way for a more sustainable future in powder packing.

Accutek Packaging Equipment Companies, Inc. stands as one of the premier privately owned packaging machinery manufacturers in the United States.

Sign up for all the news about our latest arrivals